Product details

Highlights

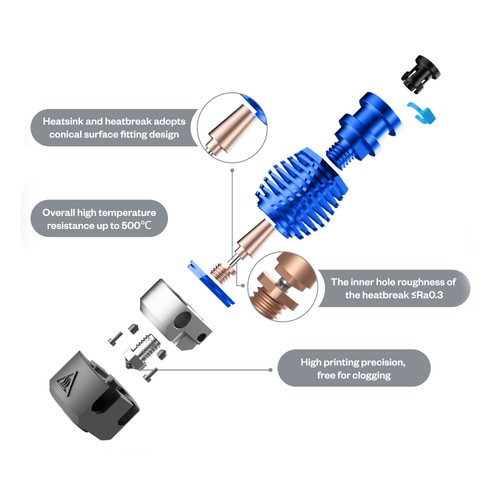

The hotend’s core parts are mainly composed of copper alloy, which has the advantage of better heat conduction.

Overall high-temperature resistance up to 500 degrees.

Heat sink and heat break adopt a conical surface fitting design.

Close-fitting increases heat dissipation contact area.

Low roughness of heat break.

The inner hole roughness of the heat break ≤Ra0.3, which allow a smoother movement of filament.

High printing precision, no filament plugging.

Specification

| General |

Brand: Phaetus |

| Specification | Nozzle Diameter: Plated copper 0.4/1.75mm, Hardened steel 0.4/1.75mm Size: φ24mmx75mm Material Processes: Aluminum heatsink Heat Cartridge: Ceramic heating element Applicable Materials: Compatible with all thermoplastic filaments, including but not limited to typical composite fiber filaments such as PLA, ABS, PETG, TPU, PP.PA, and PLA-CF, ABS-CF PETG-CF. PA-CF/GF, as well as composite filaments such as steel, wood, boron carbide, tungsten and fluorescence. |

| Weight & Size | Product Weight: 105g Package Weight: 130g Product Size(L x W x H): 10x6x4cm |

| Package Contents |

<span style="font-family: tahoma,microsoft yahei,Hexagon bar (1.27/1.50/2.00 each) |

Me***g –

High temp filaments on my Ender 3 Pro

Pa***n –

This hot end is just as good if not better since it’s newer, then the older brothers I have.

El*** –

Finished install this morning and printing my 5th print right now with it.

Ri***s –

You will need to heat up the hotend to the highest temperature you are going to print plus 10 or 15 degrees higher and then with the wrench tighten the nozzle in for a good seal so that no filament Leakes out anywhere and the nozzle stays put. Over I’d recommend it.

Aa***. –

No clogs with PLA, PETG, Nylon, or PC.

Li***r –

Prints awesome, compact size, great price

Do***l –

Just received it yesterday, started the install immediately after over viewing the kit and instructions.

Al***o –

Was a great hotend. Tips:1. Tune hotend PID for better temperature stability.2. Use high-temp boron nitride paste instead of supplied 200C rated junk.3. If you are technically inclined and feel adventurous: Calibrate your new thermistor. Original was spot on but replacement was 10-15C off. While you are at that, you may also replace stupid 4.7 kOhm pullup resistor with 1 kOhm to improve accuracy at high temperature. For calibration reference I got cheap brass nozzle, drilled a larger hole in it and potted thermocouple with the above paste. Obviously you will need something to read that thermocouple.4. Get a hardened nozzle if you want to print carbon fiber filled nylon and such.Was a great hotend. Tips:1. Tune hotend PID for better temperature stability.2. Use high-temp boron nitride paste instead of supplied 200C rated junk.3. If you are technically inclined and feel adventurous: Calibrate your new thermistor. Original was spot on but replacement was 10-15C off. While you are at that, you may also replace stupid 4.7 kOhm pullup resistor with 1 kOhm to improve accuracy at high temperature. For calibration reference I got cheap brass nozzle, drilled a larger hole in it and potted thermocouple with the above paste. Obviously you will need something to read that thermocouple.4. Get a hardened nozzle if you want to print carbon fiber filled nylon and such.

sh***m –

omg it’s super awesome